The company was founded on August 28, 2000 and entered Chuzhou Economic and Technological Development Zone in December 2003. It is a technology-based enterprise specializing in the research and development, design, production, manufacturing, and sales services of home appliance molds and equipment.

Since its establishment 20 years ago, the company has been committed to the research and development, design, production, manufacturing, and sales services of home appliance mold equipment. Its main products include vacuum forming molds for refrigerator inner liners, foaming molds for refrigerator box/door bodies, sheet metal forming molds for refrigerator door shells, punching equipment for refrigerator inner liners, vacuum forming equipment for refrigerator inner liners, as well as molds for air conditioners, washing machines, and other products. Our market customers include well-known domestic home appliance manufacturing companies such as Bosch, Changhong Meiling, Gree Jinghong, Jiangsu Shuanglu, Hisense, Nanjing Skyworth, Guangdong Wanbao, TCL, etc., and our products are exported to overseas markets.

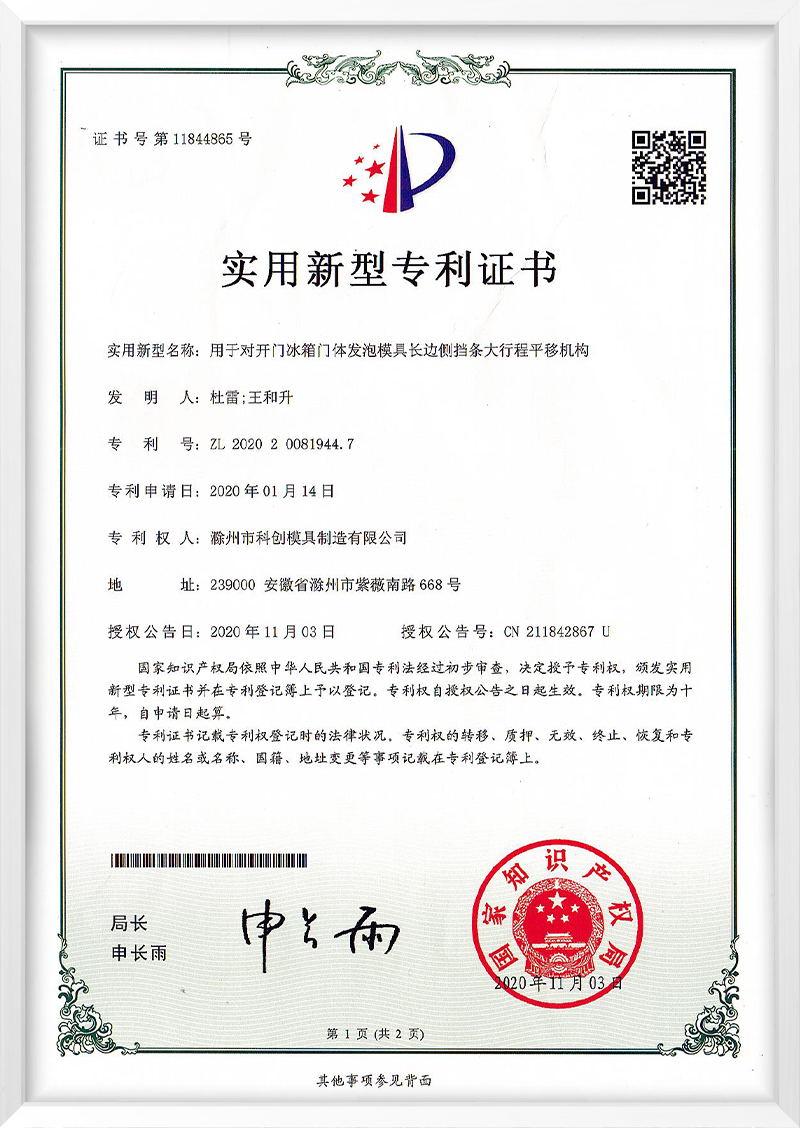

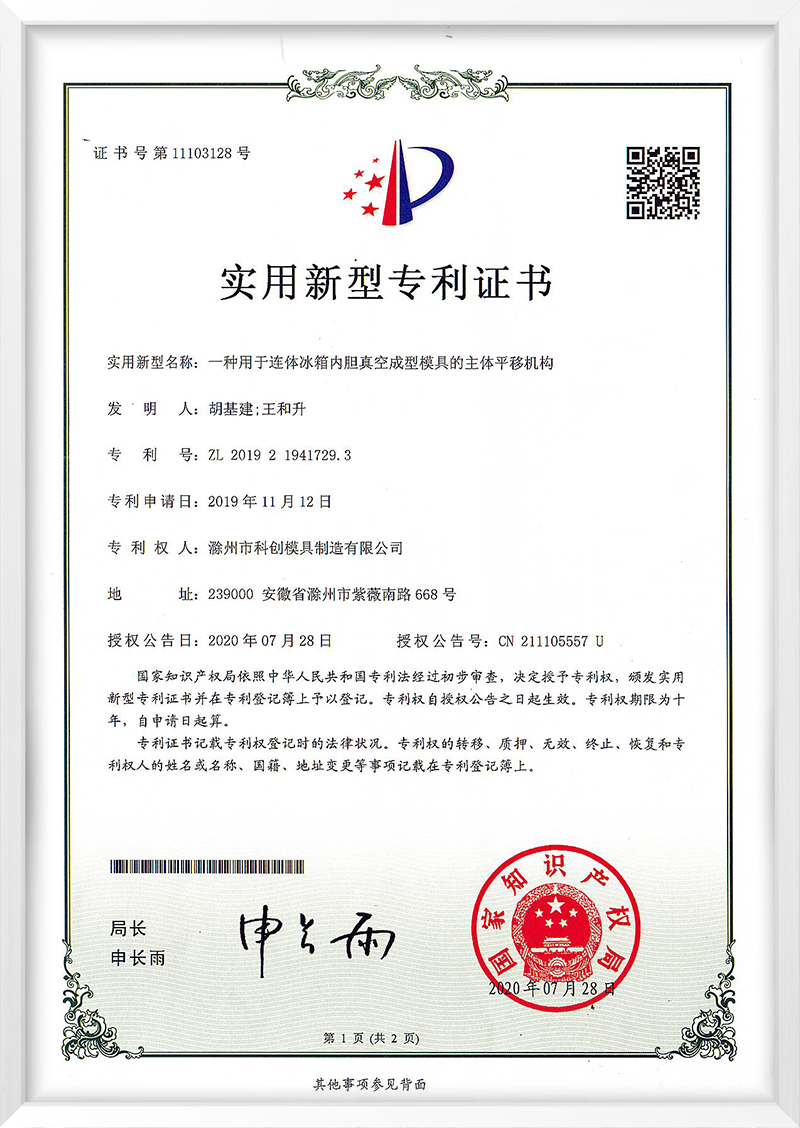

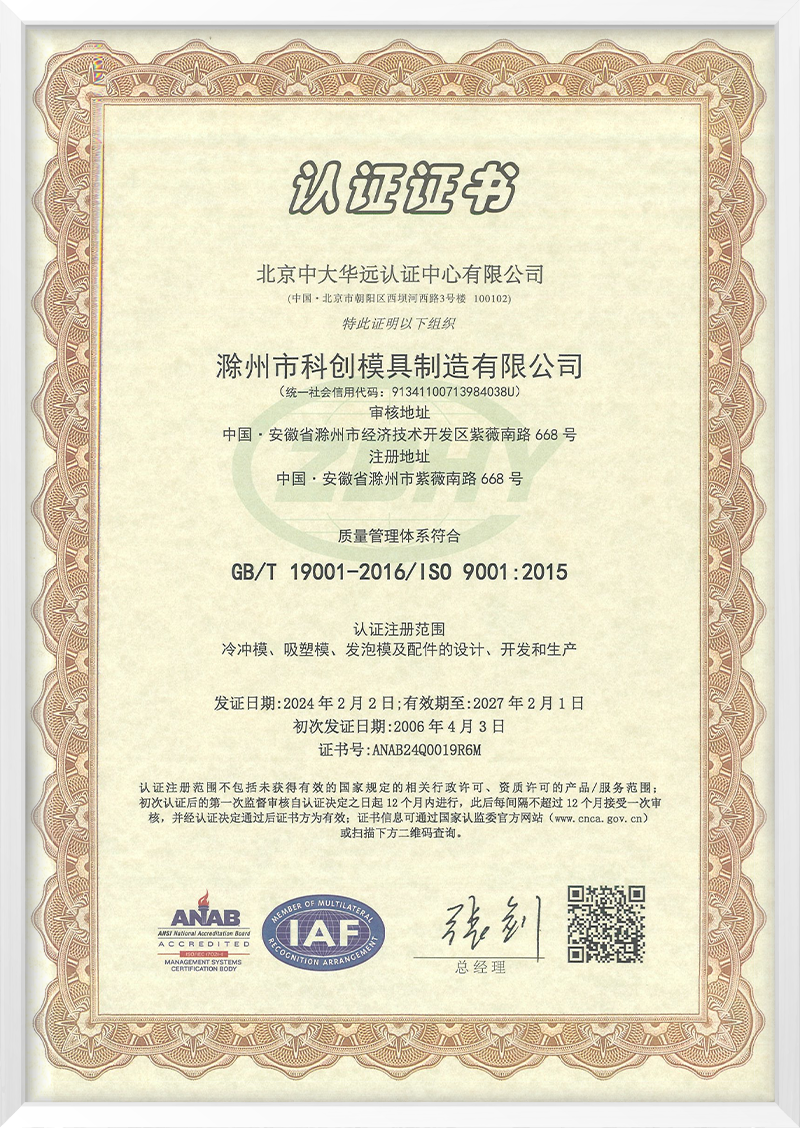

The company has established multiple municipal level research and development platforms, and actively carries out independent innovation activities while completing production and operation projects. It has undertaken 3 national, provincial, and municipal science and technology plan projects, obtained 10 authorized invention patents, recognized 12 provincial-level new products, and developed 4 sets of Anhui Province's first major technology equipment projects and other scientific and technological innovation achievements, making significant achievements in the company's continuous production and operation, innovative development, and brand building.

-

48+Patent Certificate

-

362+Certificate of Honor

-

4+Various Certifications

3 national level projects, 12 provincial-level new products, 4 first equipment sets - defining industry standards using hardcore technology